In many household plots, if their owner is engaged in the cultivation of garden crops, greenhouses are installed. These designs make it possible to grow early crops even in cold climates. Usually greenhouses are used in the spring and summer. In winter, they stand idle. But they can be exploited year-round so as not to experience a shortage of vegetables. To do this, you just need to warm the structure well. We will talk about this process further.

Greenhouse insulation methods

There are several options for warming greenhouses, differing in the cost of materials and time.

Construction of a greenhouse with high-quality thermal insulation

If you are just planning to build a durable greenhouse, you must immediately think about its thermal insulation. First of all, it is necessary to close all the polycarbonate cells that were open after cutting the material. For this, a polymer profile or mastic is used. Then, after “stitching” of the sheets, it is necessary to seal the joints and cracks with sealant, construction tape. Before assembling and installing the structure, it is recommended to take care of the foundation in order to protect the earth from freezing. Otherwise, you will need to think about how to warm the soil in severe frosts.

Then, after “stitching” of the sheets, it is necessary to seal the joints and cracks with sealant, construction tape. Before assembling and installing the structure, it is recommended to take care of the foundation in order to protect the earth from freezing. Otherwise, you will need to think about how to warm the soil in severe frosts.

Insulation of the foundation and beds

Many people think that if the construction is light, then the foundation is not needed at all. In some ways they are right, but not when it comes to the greenhouse. Here it is needed not so much to keep the structure, but to protect the soil from freezing, therefore, if you are faced with the task of warming a greenhouse built without a foundation, start with laying it.

In this case, the usual strip foundation is suitable. Its depth should be done a little more than the depth of freezing of the soil. For additional insulation, roofing material is laid on top of the foundation. Insulation is also necessary from the outside of the building. Lay a layer of sand at 40 cm and polystyrene. Often the foundation is insulated with polystyrene foam, which is wrapped in polyethylene to protect against moisture.

Did you know? In 1898, the method for producing polycarbonate was first described by the German chemist Alfred Einhorn, who invented novocaine. The discovery of the material happened by chance during research on the production of pain medication from ether. After the next reaction, a precipitate was found in the form of a transparent insoluble and heat-resistant substance.

A good option is foamglass. It is not afraid of moisture or rodents, it retains heat well, but its cost is much higher than other materials. The warming of the beds will not be superfluous. The easiest option is to create a high bed of 40 cm. You can lay a heating cable under a 10-centimeter layer of soil. It works from a normal power supply.

Well proven water heating system of the soil. This is a safer method than the previous and more effective than high beds. A water system can also be used to warm the entire greenhouse if it is not large, but the cost of this system is not small, and installing it is not easy.

Glazing sealing

No matter how well polycarbonate retains heat, its thin sheet will not protect against severe frosts, so it is necessary to create an additional layer for sealing. The easiest option is film. A plastic film lining the structure from the inside. It turns out a multilayer coating: polycarbonate with air cells inside and a film. Between them is an additional air gap.

Important! If possible, you can enhance the effect of these actions with the help of electric or thermal heaters.

A more efficient way is another layer of polycarbonate. For interior decoration, sheets with a thickness of 4 mm can be used, for the exterior - sheets with a thickness of 6-16 mm are suitable. They are placed so that the joints coincide with the supporting structural elements, and are fixed with screws with rubber washers so that there is no freezing.

Active heating

Minimization of heat loss is a significant plus while maintaining heat inside the structure, but still does not allow to provide the necessary temperature for plants in cold weather. You can’t do without heating.

Biological heating

The most affordable heating option, the principle of which is that heat is released during the decomposition of organics. To take advantage of this natural process, it is necessary to remove the soil layer in the greenhouse with a thickness of 0.8–0.9 m. A layer of expanded clay is poured onto the bottom of the formed hole. It retains heat well and is safe for plants. On top of it is a layer of organic matter (paper, thick branches, stumps). The layer will be dense, so its decomposition will be slow.

Important! The process of decomposition of organics starts when the beds are moistened through rainfall or from groundwater. The generated thermal energy will go directly to the roots of the plant.

Above - foliage, hay, mulch 18–20 cm thick. Further there should be a biofuel layer - the main source of heat. For it, compost is used mixed with manure, sawdust and shavings. This layer should be 20 cm thick. Black earth with peat additives is laid out on top. The result is that the bed rises above the rest of the soil.

Use of heating appliances

Despite all its advantages, bio-heating is not able to heat the air. This shortcoming can be corrected with the help of heating equipment.

The following options are possible:

- solid fuel furnace (involves the use of firewood, coal, briquettes. The air warms up well, but the heat can spread unevenly);

- electric heaters (easy to use, safe, heat well, able to work in tandem with heat sensors to maintain a certain temperature. Their installation is possible only in electrified areas, with large sizes of the greenhouse it will be costly for finance);

- water heaters (only possible with the location of the greenhouse near the house, heated by water, conveniently and effectively);

- infrared equipment (You can install special panels or heat lamps. Evenly warm the air, but their cost is high).

Did you know? Polycarbonate made transparent inserts in the medals of the 2014 Winter Olympics. The material was preferred due to the fact that it has a large coefficient of thermal expansion, and is also durable, ductile and convenient to work with.

Emergency insulation of the structure

You can insulate a greenhouse using the methods described above when there is a lot of free time. But there are situations when it is very urgent to insulate the structure in a short period of time. This usually happens when frosts suddenly come.

Then the following methods are used:

- From the outside, cover the structure with tarpaulin or polyethylene.

- On the perimeter of the foundation, on the outside, pour a layer of sand and cover it with sawdust, leaves, hay, straw.

- On the inside, arrange leaves of polystyrene or polystyrene wrapped in polyethylene along the perimeter. Blow out the cracks between the insulation sheets with foam.

- Before entering the greenhouse, build something similar to a vestibule and hang the door with polyethylene or tarpaulin. In the same way, you need to close the windows.

- Inside the greenhouse, place several barrels half full of humus with sawdust.

Features of warming greenhouses

The described methods of warming greenhouses are applicable for both polycarbonate and glass buildings. But there are some nuances that distinguish them.

Polycarbonate

A polycarbonate sheet is a “layer cake” consisting of two plates of polymer material with an air gap between them. This structure of the material allows it to be a good heat insulator. In addition, when using the material for the construction of greenhouses, polycarbonate sheets are overlapped, which additionally minimizes heat loss.

As a result, the structure retains heat well and there is no need to put a lot of effort into sealing it. In the end, it turns out that arranging a warm polycarbonate greenhouse is simple and not costly.

From glass

The glass structure is more reliable than polycarbonate. It is initially installed on the foundation, since its weight is not small, so the task of warming it is simplified. But this is perhaps the only positive side of glass greenhouses. In the manufacture of the design, the glasses are placed in the frame, and the frames are installed end-to-end. As a result, there are gaps between the glass and the tree, and between the frames themselves.

In addition, glass is used in one layer, since in two it is not profitable, therefore it retains heat weakly. Because of this, when warming such greenhouses, first of all, you need to take care of sealing the structure and creating an additional layer in order to better retain heat.

Additional heating tools

The fastest way to warm greenhouses with improvised means is plastic water bottles. But it can be used in the off-season, it will not help protect from frost.

In winter, as an additional heating, you can use:

- high beds with insulation of the lower layer;

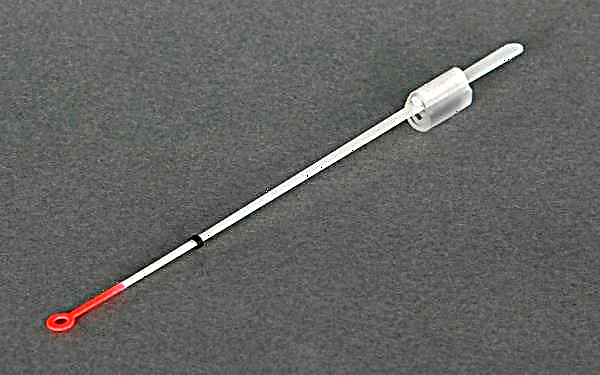

- laying along the beds of cable;

- gas heating (gas heaters, injection infrared heating pads);

- soil chimney (the stove is located outside the greenhouse, the chimney is placed in the soil);

- catalyst burners.

How to keep warm in a greenhouse

Along with the arrangement of the heating system for the structure, it is also necessary to consider how to save the received heat.

There are some simple options:

- bubble wrap (can be used for pasting the inside of the structure, retains heat well, protects against drafts, transmits light);

- division of the greenhouse into zones (the same film can be used to divide the internal space of the structure into separate sections, as a result, individual sections can be heated);

- heater if necessary (an electric heater is able to quickly pump warm air, which allows you to warm up the room in a short period of time if the temperature drops sharply);

- thermostat (allows you to maintain the temperature at a certain level);

- geotextile (Landings can be insulated with this material, it retains heat well and reduces the frequency of turning on the heater).

Insulation of greenhouses is an important and troublesome business. It is best to combine it with the construction of the structure, since it will take less time and effort. In addition, you will not need to think at the last moment how to do everything.

Insulation of greenhouses is an important and troublesome business. It is best to combine it with the construction of the structure, since it will take less time and effort. In addition, you will not need to think at the last moment how to do everything.